1. Realize computer control of electroslag furnace remelting process

2. High-precision weighing system + on-load voltage regulating transformer

3. Coaxial high current power supply system

4. High precision X-Y electrode adjustment system

5. Airtight inert gas shield

6. Electrode tip preheating device

Electroslag furnace transformer has a wide range of applications. It can not only be used to produce aviation bearing steel, superalloy, resistance alloy, precision alloy and some non-ferrous metals, but also can be used to produce large-scale high-quality alloy steel nails and large flat ingots weighing hundreds of tons. Or slabs and other special shaped castings.

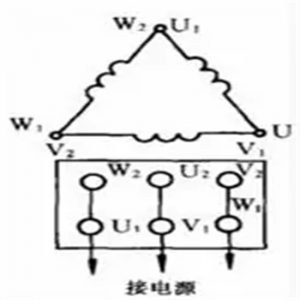

Connection Method ;

-300x300.jpg)

Core Construction

High-grade grain-oriented silicon steel core

Automated cutting with 45° full miter joints

Punch-free processing with fiberglass-free adhesive tape binding

Coil Technology

Advanced main-longitudinal insulation structure

Optimized winding design for mechanical strength

Precision-engineered insulation system

Key Features

Superior short-circuit & overload capacity

High efficiency with minimal losses

Safe and reliable operation

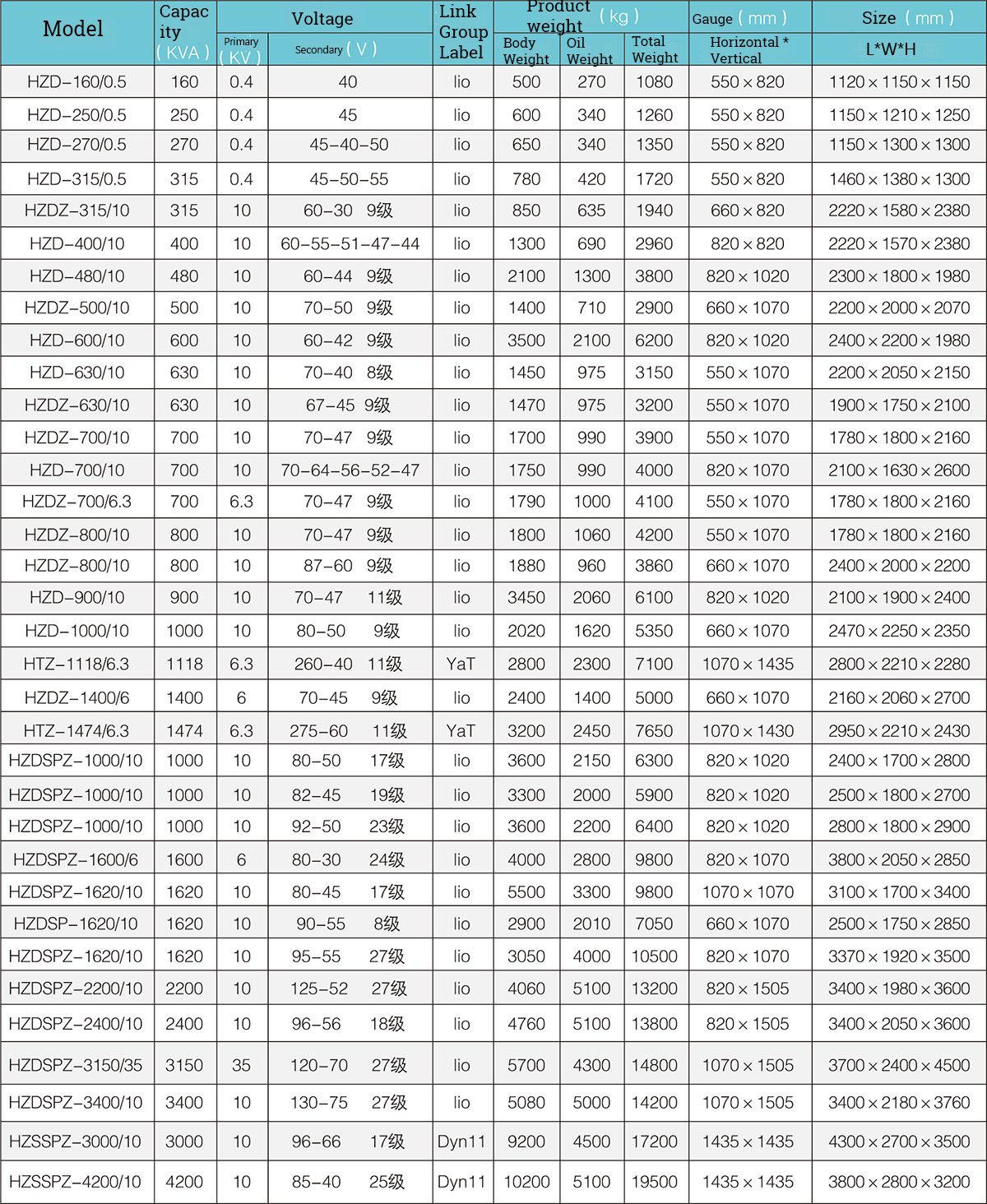

Technical Specifications

Designed for electric arc furnace steelmaking

Capacity matched to furnace size and process requirements

Two voltage regulation options:

On-load tap changing (OLTC) for large units

No-load tap changing for smaller units

Impedance variation through:

Series reactor switching (for units with reactors)

HV winding reconfiguration (for reactor-free units)

Performance

Fully compliant with smelting process demands

Robust construction for industrial environments

Energy-efficient power conversion

Transformers always been delivered by ship,train or truck for oversea,which with main active body in bulk and accessories in wooden cases.

Considering differences in voltage, frequency and other speciality of transformer product in different countries and regions,our product can be customerized according to your requirements.

Yes. We offer at least two years guarantee for all of our transformers.

Yes. It’s available. We are responsible for each set transformer’s testing.

Yes. For our products,we all show after-sale guide installation adn question inquiry

All products of the company have passed the national type test like UL、CUL、CCC、CQC、 CTQC、CE、SGS and other national mandatory product certification, and has a perfect quality, occupational health and environmental management system certification system. And also, our products have passed ISO9001, 14001, 45001 and other international quality system certification.

Contact a Xinghe representative today to learn more about our Transformer.